13 Tips for Your Ultimate Warehouse Design & Layout

We share 13 tips for optimizing your #warehouse design, storage, and layout to optimize factory efficiency. Read them here!

We recently spoke to Cody Adams, Formaspace’s Production Manager, to get his recommendations on how to improve warehousing operations at your facility. While Cody wants to issue a disclaimer right off the bat saying, “there’s not one perfect warehouse layout design for everyone because every industry and warehouse is unique,” he hopes you’ll find the following collection of tips useful:

TIP 1: Learn More about Your Warehouse Operations by Engaging Outside Experts to Assess Your Warehouse Layout

Be open to the idea of getting expert advice. Warehouse design has changed a lot in recent years, as large distribution centers (DCs) have moved away from single channel to multichannel inventories and even smaller warehouses have begun to automate many operations.

An experienced set of eyes can quickly scan your warehouse layout and spot signs of trouble, which can range from visible dust settled on products in storage (indicating obsolete inventory) to inefficient use of use of dock space (such as when put-away areas aren’t cleared out quickly enough).

Formaspace offers its Rapid Plant Assessment consulting services to warehouse and factory operators. In as little as 30 minutes, we can offer practical suggestions to help make your operations more efficient.

TIP 2: Use the 5S Process to Improve Efficiency and Reclaim Non-Productive Warehouse Storage Space

If your warehouse has been in operation for many years, “stuff” has a way of accumulating in places that should be used for valuable inventory and stock.

We recommend the 5S process popularized by “The Toyota Way” to reclaim floor space. Once you reclaim your floor space, go vertical for increased storage density.

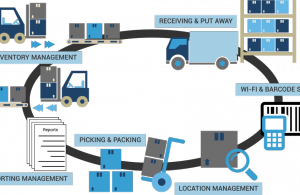

TIP 3: Implement a Warehouse Management System (WMS) to Collect and Analyze Measurable Historical Data

In today’s competitive business environment, data collection is imperative. Today’s Warehouse Management Systems (WMS), not only track inventory, they collect critical operational data.* Often, WMS can make radical recommendations, such as changing your product slotting philosophy away from conventional product value-based ABC categorization toward often counter-intuitive yet highly-efficient approaches, such as floating inventory warehouse layouts.

*You can also rely on insights garnered from Process Mining tools, which we’ve written about recently.

We recommend implementing automated asset tracking data collection methods to avoid downstream errors — manual entry is a no no. Go a step further and assign unique tracking numbers to assets, don’t rely on serial numbers (which are often not unique). And don’t just track movable assets, track your fixed assets as well.

Armed with accurate data, you’ll be able to improve forecasting. For example, you can use asset tracking to find out how often inventory is picked throughout the year — use drop shipping directly from the manufacturer for SKUs with low seasonal demand.

TIP 4: Identify Warehouse Best Practices and Make Realistic Goals for Improving Your Warehouse Design

Many consultants use the acronym FAST (which stands for Flow, Accessibility, Space, and Throughput) when making recommendations to help you achieve warehouse design best practices. The FAST acronym is also useful for communicating upward to senior management (KPIs can be associated with each category).

Acronyms aside, it’s important to find current information on best practices in the warehousing industry that can apply to your individual circumstances (e.g. an apples-to-apples comparison). Trade associations and other industry information sources can help.

Armed with a sense of industry best practices (such as product order cycle times), you can establish your own set of measurable metrics to track and improve upon.

Here are some key areas to work on:

Establish a logical, repeatable, efficient returns process. This will improve warehouse overall efficiency.

Consider implementing a “lean” warehouse philosophy, focusing on reducing material handling time, reducing loading and unloading times, reducing time locating lost inventory, improving communication to customers, and increasing your supply chain.

Use your improved inventory analysis to identify where to invest next to maximize ROI. For example, investments in automation may make sense for some inventory, or (as IKEA has done) you might build a second warehouse solely dedicated to your highest volume, fastest turnover inventory.

TIP 5: Communicate Up-to-the-Minute Warehouse Operations across the Organization

Sharing is caring. By sharing real-time warehouse information with key staff throughout the organization, you can realize significant improvements in cycle times while avoiding the need to field distracting “where is my stuff” calls from the rest of the organization. (The visibility to executive management doesn’t hurt either.)

TIP 6: Rely on Warehouse Management System (WMS) Data to Organize Your Warehouse Layout

If you have visited or seen videos of industry-leading distribution centers, such as those from Amazon*, you may have become mesmerized by the seemingly random pathways taken by robots fulfilling orders and restocking inventory. It’s an uncomfortable shift for those who grew up on the logic of ABC warehouse layouts, yet we have solid evidence that WMS can sequence orders and organize highly efficient workflow (often using floating locations in the space available) if you only let it.

Having insight from the WMS is also particularly useful when you experience a surge of incoming inventory, such as during seasonal sales activities.

And if you are new to this level of automation, don’t forget that implementing a robust WMS now will help you communicate supply information directly to your suppliers and customers in the future.

*Amazon is a Formaspace customer.

TIP 7: Focus Your Warehouse Layout Design Decisions on the Dock Operations

The dock area can be the most congested and potentially most dangerous area within your warehouse layout.

When designing new warehouse facilities, consider taking advantage of the newest trends, including just-in-time cross-docking. Cross-docking is a technique where fresh inventory is unloaded directly from the inbound vehicle(s) then immediately re-loaded onto outbound vehicles — all without having to store the inventory in the warehouse. You’ll need to allocate additional space and multiple docks to perform these operations without creating choke points that impede flow.

For inventory unloaded at the dock, don’t allow put-away areas to build up inventory. Make sure they are cleared out daily to avoid congestion and avoid product damage.

TIP 8: Organize SKUs in Bins and Re-slot Pick Positions Often to Reduce Pick Times

Do you know where your most valuable, high-volume products are being stored? The answer should be “as close as possible to the shipping area” to reduce picking steps.

Perform an ABC categorization (using WMS data) to identify these most valuable, high-turnover products and get them closer to the shipping area.

But forget about keeping products from the same manufacturer together. That’s old school. Instead, keep each SKU in its own bin. (Don’t put more than one SKU in a bin as that slows down the picker and leads to increased errors.)

With everything in bins, it’s easy to re-slot as needed. It’s not a once a year activity anymore — take the opportunity to re-slot your highest profit/volume products every day to maximize efficiency.

TIP 9: Think Twice Before Expanding Your Warehouse Design and Storage

Are you really running out of warehouse space? Or are you not using the space you have efficiently enough?

If you think you’re running out of space, revisit Tip Two above and perform a thorough 5S program to clear your aisles and clean out inventory that’s not where it should be.

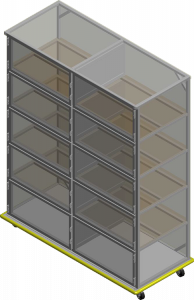

Then, take advantage of vertical space. Pallet racking is safer and more secure than stacking pallets directly on top of one another. Formaspace can help you built custom mobile storage solutions to keep things tidy and organized.

One of our Formaspace clients avoided spending $1 million annually by avoiding the need to acquire new space just by making better use of their existing square footage.

We can also help you create highly-efficient, customized packing stations that will increase throughput. Ask a Formaspace Design Consultant about how this works. (Use the form at the end of the article to request a call.)

TIP 10: Ensuring the Health and Safety of Workers, Your Most Important Asset

Choices made in warehouse layout and enforcement of operational safety standards can help prevent worker accidents and save lives. Docks are particularly dangerous: make sure everything is secured, keep aisles clean, avoid forklifts approaching dock edges, enforce safety protective equipment rules, and have all operators certified to operate heavy equipment.

Make it clear that safety is your top priority. Involve employees in creating a safety committee that is responsible for creating emergency response plans for accidents, including hazardous spills and fire.

Avoid workplace injuries, such as falls and back injuries by providing appropriate material handling procedures (including mechanical lifts for heavy items).

Use ergonomic furniture designs with height-adjustable surfaces for your workers (such as packers) that can adjust on the fly to fit different employee heights.

TIP 11: Don’t Overlook Solutions Once Considered Outside of Traditional Warehouse Operations

Warehouse operations are no longer an island. As warehouse operators wring the last bit of efficiency out of their internal operations, many find that outside factors can have a major positive impact on making things more efficient.

Improved communication with your suppliers and your customers is key. If you have advance notice of sales promotions, new product introductions, unexpected demand spikes or supply shortages, you can make smarter decisions when setting the minimum holding stocks necessary to cover lead times.

As we alluded to earlier, the largest and most advanced companies (think Walmart or Amazon) take this a step further with complete visibility into their supply chains.

It also goes without saying that buying better products from more reliable suppliers can make your warehouse operations more efficient.

Don’t be a hostage to open delivery hours. Request advanced shipping notifications from your suppliers and establish predictable appointments on the calendar. This will help you plan for major shipments by clearing space in advance and making sure your warehouse is fully staffed during peak hours.

Finally, consider ‘out of the box’ solutions, including third-party (3PL) warehousing and drop shipments from the manufacturer for items that don’t fit into your warehouse profile.

TIP 12: Let ROI Determine Roll-out of Automation Implementations

Automation is coming to your warehouse if it hasn’t already. Amazon is creating an end-to-end supply chain, starting with its consumer-based Alexa personal assistant that can take orders by voice command.

What level of automation makes sense for you? The answer lies in analyzing the data collected by your WMS or process mining systems. This historical data, combined with future volume projections, will help you perform the necessary analysis to determine the Return-on-Investment and argue for or against automation.

At present, automation solutions tend to work best for highly repeatable tasks; however, as robots become more flexible and trainable, they are increasingly taking on more complex, changeable work. See other Formaspace articles on robots in industrial settings for more information:

Should Robots Replace Humans in Your Industrial Facility?

Is Digitization of Manufacturing and IoT the New Industrial Revolution?

Amazon’s Amazing Fulfillment Warehouse Strategy

Robot Manufacturers demonstrate “Industry 4.0” Innovations at Hannover Messe

Robot Companion Workers Take Stage on the Factory Floor

Remember, you don’t need to do a wholesale replace when pursuing an automation strategy — in fact, that’s likely a recipe for disaster. Instead, identify which activities would provide the highest ROI at the lowest risk and start from there.

If you have multiple facilities, it might be useful to perform testing at one facility before making changes across the board. This way you can confirm savings by making an apples-to-apples comparison.

TIP 13: Constant Renewal and Improvement is Not a Once a Year Task

Inventory control audits? They are not just an annual thing anymore. Perform these at least every quarter.

The same goes for product re-slotting, as we mentioned above. That needs to happen as often as every day for your highest-profit, highest-volume products.

The bottom line?

You should take the opportunity to measure, analyze, and renew everything about your operations throughout the year.

We have done the same here at Formaspace. During our most recent factory and warehousing reorganization, we designated new special order areas, revised access to our raw metal staging areas, and updated the warehouse layout to increase the efficiency of our laminate storage.

We hope this list of tips will help you optimize your warehouse design, warehouse storage, and warehouse layouts.

To learn more about how Formaspace can help you with our Rapid Plant Assessment consulting services and our full line of industrial furniture, please fill out the form below, and one of our friendly Design Consultants will be in contact with you today.

Brooke Turner

Formaspace

8002511505

email us here

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.